| < Prev | Home | Index | P1 | P2 | P3 | P4 | Next > | ||

| A01 | A02 | A03 | A04 | A05 | A06 | A07 | A08 | A09 | A10 |

| A11 | A12 | A13 | A14 | A15 | A16 | A17 | A18 | A19 | A20 |

| A21 | A22 | A23 | A24 | A25 | A26 | A27 | A28 | A29 | A30 |

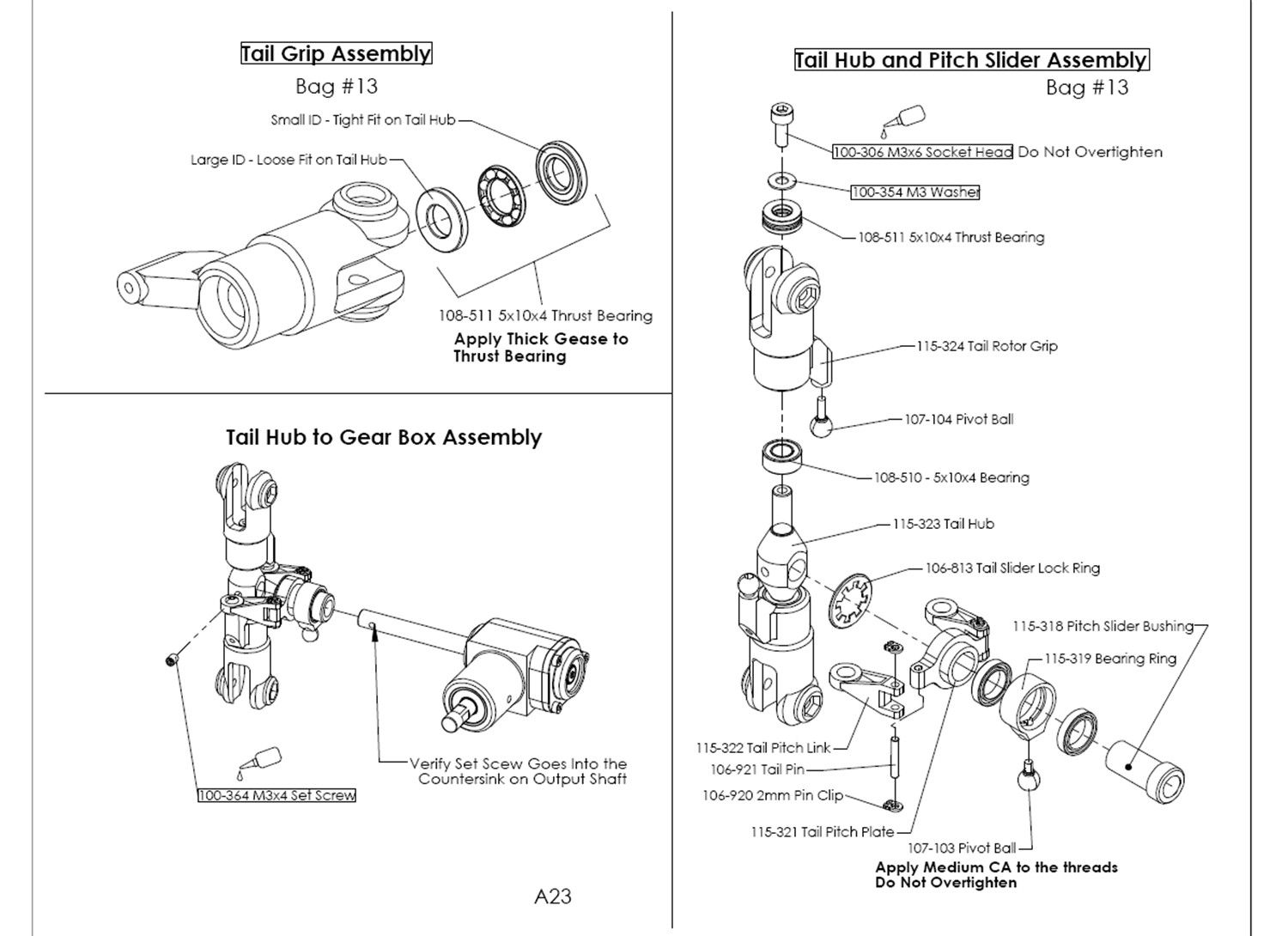

The pin clips (106-920) can be tricky to get on. See page A17 for some tips.

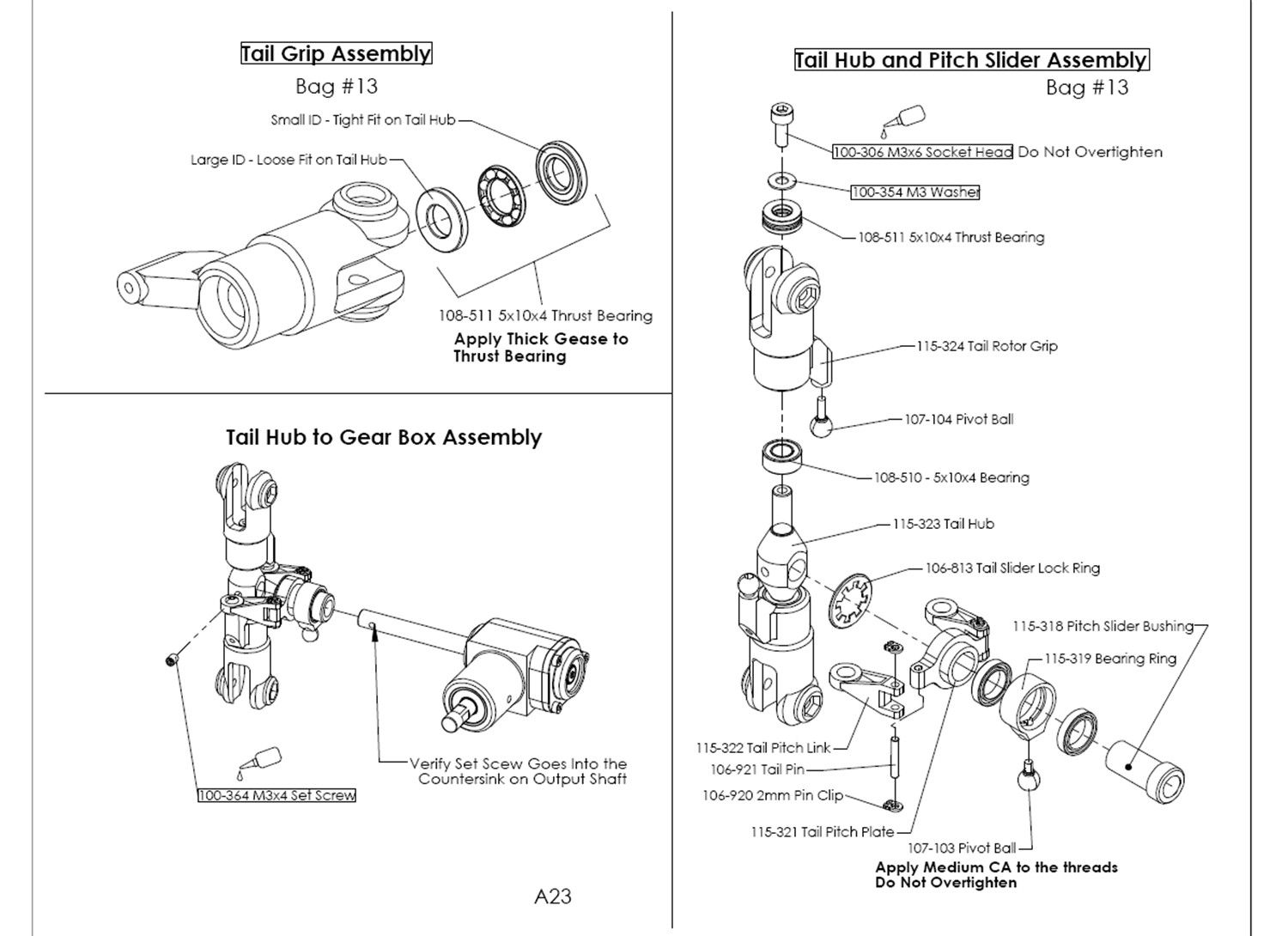

Double check the inner diameters of the thrust bearings (108-511).

Be sure there is no play in the tail grips along the hub shaft (115-323). Some hubs were machined with the shaft too short making the grip assembly too tight when screwed in.

Check the orientation of the Pitch Plate. The collar is towards the boom.

The tail hub set screw (100-364) is critical. Make sure it is lined up with the countersink as noted in the directions. If tightened properly, both the set screw and the tail output shaft (115-312) should be flush with the hub assembly

CA the 106-813 tail slider lock ring so it won't slip

If you have a tail wag, try trimming down the outer edge of the thrust bearing with the smaller inner diameter (ID).

This is the one closest to the blade. If the bearing assembly sticks to the side of the tail grip then the bearing can't do it's job of allowing the grip to move smoothly and freely.